Scaffolding Height Requirements in Australia: What You Need to Know for Compliance

In Australia scaffolding height requirements are a vital part of working at height. Scaffolding is required for any work 4 metres or more in height. This guideline is to prevent falls and injuries and to ensure compliance across all construction sites.

Knowing the specific requirements for different types of scaffolding is important for construction workers. Each state in Australia has its own regulations and national standards for design and operation of scaffolding systems. By knowing the laws you can ensure compliance and improve site safety. At Reliable Access safety and compliance is paramount to our business. All of our scaffold designs, assembly techniques, and installations are complainant to the following standards:

- AS/NZS 1576.1 – Scaffolding General Requirements

- AS/NZS 4576 Guidelines for Scaffolding

- AS/NZS 1657 Fixed Platform, walkways, stairways and ladders. – This standard covers fixed platforms and their role in scaffolding systems, including requirements for their construction and use to ensure safety and compliance.

- AS/NZS 1428.1 Design for access and mobility

With laws in place the construction industry is better protected. Knowing scaffolding height requirements not only protects workers but also the culture of safety in the industry. Work health and safety regulations, are fundamental to scaffolding legal requirements and help prevent workplace accidents and ensure compliance with Australian standards.

Scaffolding Regulations in Australia

Scaffolding regulations in Australia are for safety in construction and maintenance work at height. These are governed by national and state laws.

A key national standard is the AS/NZS 1576 series which covers scaffold design, materials and safety requirements. Each state may have additional codes for local needs.

In Australia scaffolding is required for any work 4 metres or more in height. This is to prevent falls which are a leading cause of injury and death in the workplace.

Key components of scaffolding regulations are:

- Load capacity limits: Scaffolds must be able to support the intended weight.

- Materials standards: Acceptable materials for scaffolding structures.

- Training requirements: Workers must have proper training and when necessary a high risk work licence.

Employers must also implement proper safety measures including PPE and regular inspections of scaffolding set up. A competent scaffolder must inspect the scaffolding system at scheduled intervals to ensure safety and compliance. These inspections are critical to site safety and must be properly documented. Protecting employees’ health and work health is essential. Adhering to regulations helps prevent workplace hazards and ensures compliance with health and safety laws.

Following these standards not only protects workers but also compliance with construction industry laws. For more information on specific requirements see Safe Work Australia guidelines.

How to Determine Scaffolding Height Requirements

Knowing the specifics of scaffolding height requirements is important for safety in construction and maintenance work. Scaffolding work includes all activities related to the erection, use, and dismantling of scaffolds. Several factors affect these regulations and the method of calculating safe working heights, including risk assessments that must consider hazards such as falling objects and the proper management of objects on scaffolding.

Factors that affect height regulations

Several factors determine the height regulations for scaffolding in Australia. Legislative standards play a big part with national laws and state specific rules setting the minimum requirements for safety.

The type of work being done is also important. Higher risk work may require more stringent requirements. For example construction work has more regulations than maintenance work.

Other factors are the type of scaffolding system and the structure of the scaffold itself, as different scaffold structures may have specific height limitations based on their design. Environmental conditions and the experience of the workers must also be assessed to determine the height limits for safe operation.

Safe Working Heights Calculation

To calculate safe working heights refer to Australian standards such as AS/NZS 1576.1:2019. This standard covers design and operation of scaffolding systems.

One of the key things is to determine the height at which scaffolding is required. According to regulations scaffolding is required for work 4 metres or more in height.

Also consider the maximum load capacity of the scaffold to ensure safety. This includes calculating the weight of workers, equipment and materials on the scaffold. Risk assessments must also be done to identify any height related hazards and comply with safety protocols, , including proper dismantling procedures in accordance with standards such as AS/NZS 1576 to ensure safe disassembly and worker protection.

Compliance and Safety Standards

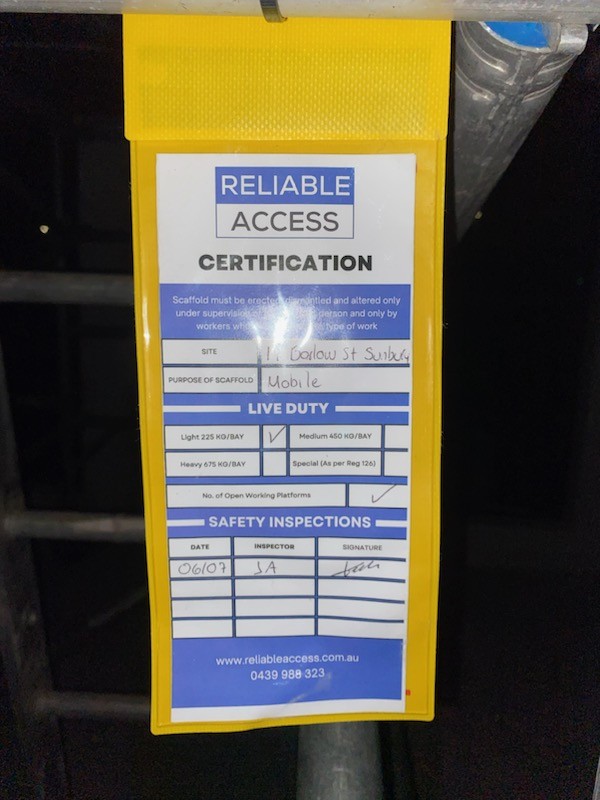

Knowing the compliance and safety standards is important for worker safety during scaffolding operations. Compliance with safety standards, including the use of scaffolding tags, helps prevent accidents by ensuring that only safe and inspected scaffolds are used. Following these standards minimises risks and maintains industry standards.

Implementing a tag system as part of your safety protocols is essential for scaffolding compliance, as it provides clear visual indicators of inspection status and helps enforce proper safety measures.

Australian Standards and Codes of Practice

The main framework for scaffolding safety in Australia is the AS/NZS 1576 series of standards. These standards cover scaffolding design, construction and maintenance so that structures are stable and safe for workers.

Key components of these standards are:

- Design Requirements: Materials and load capacities.

- Load Management: Maximum loads for different types of scaffolding.

- Safety Measures: Mandatory use of personal protective equipment (PPE) and fall prevention systems.

Local councils may also have additional codes of practice which vary by region. Compliance with both national and local regulations is important for legal and operational reasons.

Inspection and Certification Procedure

Regular inspection and certification of scaffolding systems is part of the safety compliance. Australian regulations require scaffolding to be inspected by a qualified person before use and at regular intervals after.

Key inspection points are:

- Structural Integrity: Check for any signs of wear or damage.

- Setup Compliance: Ensure scaffolding is set up according to standards.

- Load Verification: Confirm the system can support the intended loads.

Certification must be documented and records must be kept for audit purposes. Frequent inspection and correct documentation minimises risks associated with scaffolding and creates a safer working environment.

At Reliable Access prior to commencing an inspection, our team will allocate a Licensed Scaffolder individual who will be responsible for the onsite inspection.

Risk Management and Fall Prevention

Risk management is key to safety during scaffolding operations. Identifying hazards and controlling them can reduce falls and injuries. Effective risk management also helps protect workers from becoming injured while working on scaffolding.

Hazard Identification and Control Measures

Hazard identification is the first step in risk management. Common hazards in scaffolding are unsteady platforms, inadequate guardrails and adverse weather conditions. Workers must do regular inspections to detect these hazards before work starts.

Control measures follow hazard identification.

- Guardrails to prevent falls from height.

- PPE (harnesses) for workers.

- Proper scaffolding techniques during setup and dismantle.

Clear communication among team members also helps to reinforce safety protocols so everyone knows what the hazards and safety controls are. Ensuring workers are aware of hazards and safety controls is essential for maintaining a safe work environment.

Business Implications of Scaffolding Compliance

For businesses in the construction industry, scaffolding compliance is not just a legal requirement—it’s a vital part of protecting workers and the company itself. Failing to comply with scaffolding regulations can lead to significant fines, legal action, and even the suspension of business operations. Regulatory authorities such as SafeWork closely monitor construction sites to ensure that scaffolding is properly erected, maintained, and dismantled according to industry standards.

Employers are responsible for providing workers with the correct safety gear and ensuring that all scaffolding equipment is maintained and used properly. This commitment to safety helps prevent workplace accidents and injuries, which can have far-reaching consequences for both workers and the business. A single incident involving unsafe scaffolding can result in costly claims, increased insurance premiums, and damage to the company’s reputation within the industry.

By prioritising compliance, businesses can reduce the risk of accidents, avoid significant fines, and demonstrate their commitment to safety and professionalism. This not only protects workers’ lives but also strengthens the company’s standing with clients, regulatory bodies, and the wider construction industry.

Insurance and Liability for Scaffolding Projects

Insurance is a critical safeguard for any construction project involving scaffolding. Adequate insurance coverage protects employers from the financial risks associated with workplace accidents, injuries, and property damage. In the event of an incident, having the right insurance can mean the difference between a manageable claim and a devastating financial loss.

Employers must also ensure compliance with regulations regarding scaffolding tags, such as yellow tags, which indicate the inspection status and safety of the scaffold. Proper tagging is essential for minimizing liability and demonstrating that the scaffolding has been properly inspected and maintained. If an accident occurs and the scaffolding is found to be non-compliant or improperly tagged, employers may face increased liability and insurance claims.

By maintaining up-to-date insurance and adhering to all tagging and compliance requirements, businesses can protect themselves, their workers, and their assets. This proactive approach is critical for managing risks and ensuring that any workplace accidents or injuries are handled efficiently and in accordance with industry regulations.

Legal Considerations for Scaffolding Hire

When hiring scaffolding equipment, businesses must pay close attention to legal requirements to ensure full compliance with industry regulations. This includes verifying that all scaffolding is properly inspected before use and that it is maintained throughout the duration of the project. Employers are also responsible for providing workers with the correct safety gear and ensuring that only trained personnel handle scaffolding equipment.

A key legal requirement is the use of scaffolding tags—green tags for safe use, yellow tags for caution, and red tags to indicate that the scaffold is unsafe and should not be used. These tags must be clearly displayed at eye level and updated after every inspection to communicate the current safety status of the scaffold. Failure to comply with tagging regulations or to ensure that scaffolding is properly inspected can result in significant fines, legal liabilities, and increased risk of workplace injuries or accidents.

By staying up to date with legal obligations and maintaining rigorous inspection and tagging procedures, businesses can minimize the risk of failure, protect their workers, and avoid costly penalties. This commitment to compliance is essential for maintaining a safe and reputable operation in the construction industry.